Sanyu Digital Inverter Pulse Gas Shielded MIG Welder Arc Welding Machine

Appearance: Performance characteristics 1.Fully digital control system for precise control of the welding process and st

Description

Basic Info

| Model NO. | MIG-350/ MIG-500 |

| Cooling Way | Air Cooling&Water Cooling |

| Shielding Gas | Argon Gas |

| Control | Semi-Automatic |

| Frequency Range | Low Frequency |

| Electric Current | Pulse |

| Transport Package | Standard Export Wooden Box |

| Trademark | SANYU STAR |

| Origin | Shanghai |

| HS Code | 85153190 |

| Production Capacity | 10000 Sets Per Month |

Product Description

Appearance:Performance characteristics

1.Fully digital control system for precise control of the welding process and stable arc length.

2.Full digital wire feeding control system, wire feeding is precise and stable.3.The system has a built-in welding expert database that automatically intelligently combines parameters.4.The operation interface is friendly, and the unitary adjustment mode is easy to grasp.5.The welding spatter is extremely small and the weld bead is beautifully formed.6.10 sets of welding programs can be stored to save operating time.7.The special four-step function is suitable for welding metals with good thermal conductivity. The arc is arc-shaped and the welding quality is perfect when the arc is closed.8.It has various interfaces to connect with welding robots and welding machines.9.Soft-switching inverter technology can improve the reliability, energy saving and power saving of the whole machine.*The series of welding machines are manufactured in accordance with the standard GB15579.1-2013 "Arc welding equipment part 1: welding power supply".

Supply voltage quality

The waveform should be a standard sine wave with an effective value of 380+10% and a frequency of 50Hz/60Hz.The unbalance of the three-phase voltage is <=5%.Power supply technical parameters.

Basic parameters:

| Welder model | MIG-350P | MIG-500P |

| Rated input voltage | Three-phase communication,380V±10%,50Hz | |

| Rated input current (A) | 25A | 38A |

| Rated output capacity | 16 KVA | 25 KVA |

| Output no-load voltage (V) | 65V±5% | |

| Rated load duration | 60% | 60% |

| Power factor COSφ | 0.93 | |

| Efficiency η | 90% | |

| Dimensions (mm) | Water cooling:965×472×925 / air cooling:965×472×686 | |

| net weight | Water cooler :70kg / air :52kg | Water cooler:73kg / air:55kg |

| Welder type | MIG-350P | MER-500P |

| Rated current (A) | 10~350 | 10~500 |

| Thermal arc current (HOTI) | OFF/ON | |

| Factory Reset (DFLT) | NO/YES | |

Argon arc welding parameters

| Welder model | MIG-350 | MIG-500 |

| Rated current (A) | 10~350 | 10~500 |

| Arc current (HOTI) | 10~200A | |

| Current ramp up (UPSL) | 0.1~10s | |

| Air time (GPR) | 0.1~20S | |

| Gas lag time (GPO) | 0.1~20S | |

| Four-step arc current (CRAT) | 10~100% | |

| Current descent (DWSL) | 0.1~10s | |

| Welder specifications | MIG-350 | MIG-500 | |

| Rated current (A) | 30~350 | 30~500 | |

| Plate thickness (mm) | 0~25 | ||

| Wire feeding speed (m/min) | 1~22 | ||

| Arc length | -99~99 | ||

| Arc force | -50~50 | ||

| Control mode (CNTR) | LOCL/REMT | ||

| WIRE (material) | STEEL CN19 AlMg5 AlSi5 Al CuSi3 CuSi CuAl9 | ||

| Wire diameter (DIRM) | 0.8,1.0,1.2,1.6 SP | ||

| Air time (GPR) | 0.1~20S | ||

| Slow wire feed speed (FDC) | 1.0~10M | ||

| Initial current (I-S) | 10~200% | ||

| Arc current (I-E) | 10~200% | ||

| Four-step fall time (DWSL) | 0.1~1.0S | ||

| Four-step arc current (CRAT) | 10~100% | ||

| Gas lag time (GPO) | 0.1~20S | ||

| Burnback time (BURN) | 0.01~1.0S | ||

| Factory Reset (DFLT) | NO/YES | ||

| Double pulse adjustment parameter | |||

| Double pulse frequency (TPHz) | 0.1H~5.0H | ||

| Double pulse current size (TPBA) | 20%~80% | ||

| Double pulse duty cycle (TPBT) | 20%~80% | ||

| Double pulse voltage (TPBU) | -50~50 | ||

| High speed vertical adjustment parameter | |||

| Vertical welding frequency (UPHz) | 0.1H~5.0H | ||

| Short circuit transition duty (UPD2) | 20~80% | ||

| Short circuit transition current (UPC2) | 60~250A | ||

| Short circuit transition voltage (UPU2)(UPU2) | -50~50 | ||

| Short circuit transition inductance (UPI2) | -50~50 | ||

| High speed pulse welding adjustment parameters | |||

| High Speed Pulse Welding Increment (SPS) | 0~50% | ||

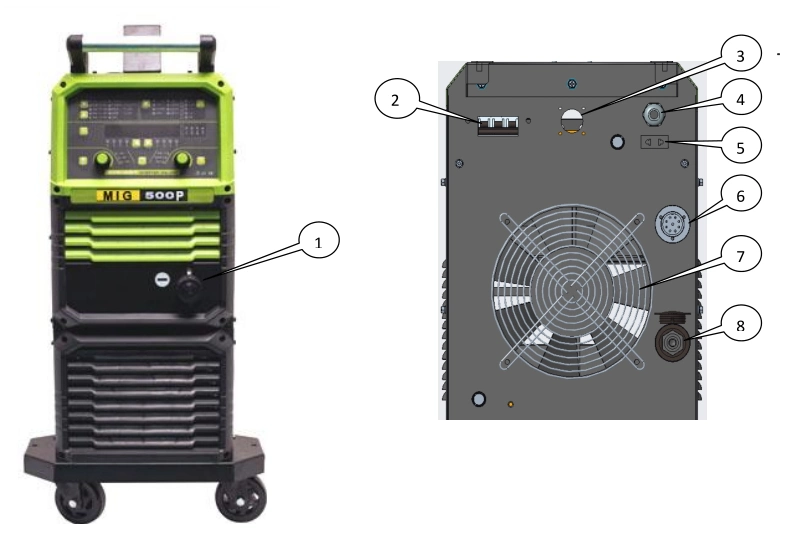

The front and rear panel controls and interfaces of the welder are shown below.

1.Welder output socket (-)2.Air switch3.External device interface4.Power cord5.Heating power outlet6.Wire feeder control socket7.Fan8.Welder output socket (+)

Prev: CNC Automatic Spot Welder Spot Welding Machine

Next: MIG DN80-DN400 Automatic Pipe Welding Machine with Seam Tracking Function

Our Contact

Send now