Automatic CNC Hydraulic Welding Section Steel Structure Member Facing Pipe Box Cross I H Beam End Face Milling Machine

Overview Package size per unit product 1500.00cm * 600.00cm * 1000.00cm Gross weight per unit product 15000.000kg A. Usa

Description

Basic Info

| Model NO. | DX0820~ DX6080 and CNC DX1010 ~ DX3535 |

| Certification | CE, ISO9001 |

| Standard | GB, ANSI |

| Customized | Customized |

| Material | Metal |

| Application | Metal Cutting Machine, Metal Straightening Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Coating Machinery, Metal Casting Machinery, Steel Structure Machining Machine |

| Control | CNC or Relay Control |

| End Face Milling Speed | Inverter or CNC Control |

| Workpiece Clamp | Hydraulic Drive, Racks Specifically Designed |

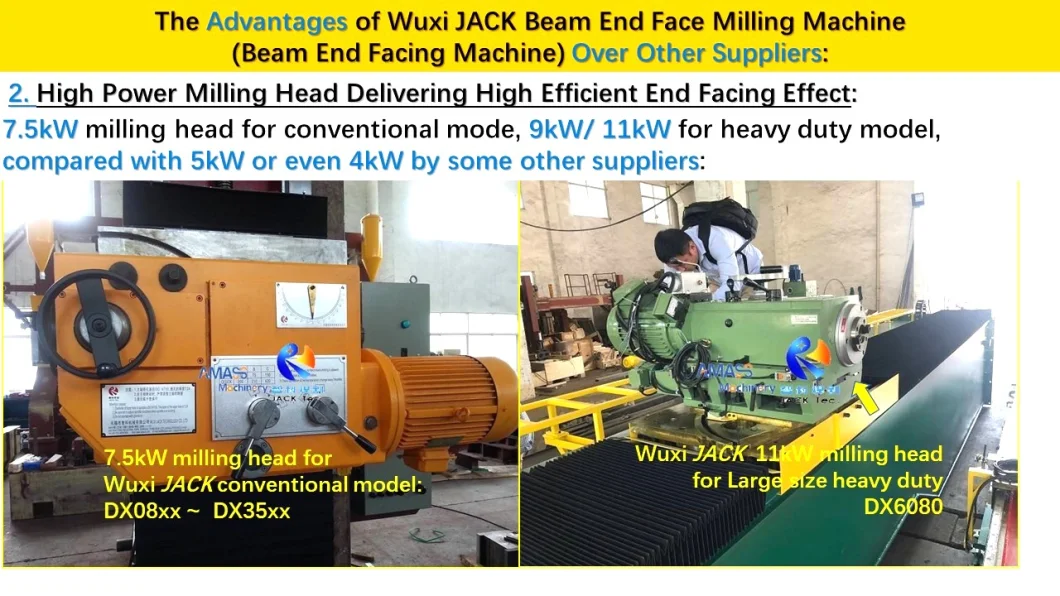

| Milling Head | 7.5/ 9 /11 Kw |

| Workpiece Type | T Cross I H Beam, Pipe, Special Shape Part |

| Working Style | Automatic, High Speed |

| Workpiece height | From 800mm to 6000mm |

| Working Speed | Continuous adjustable and display |

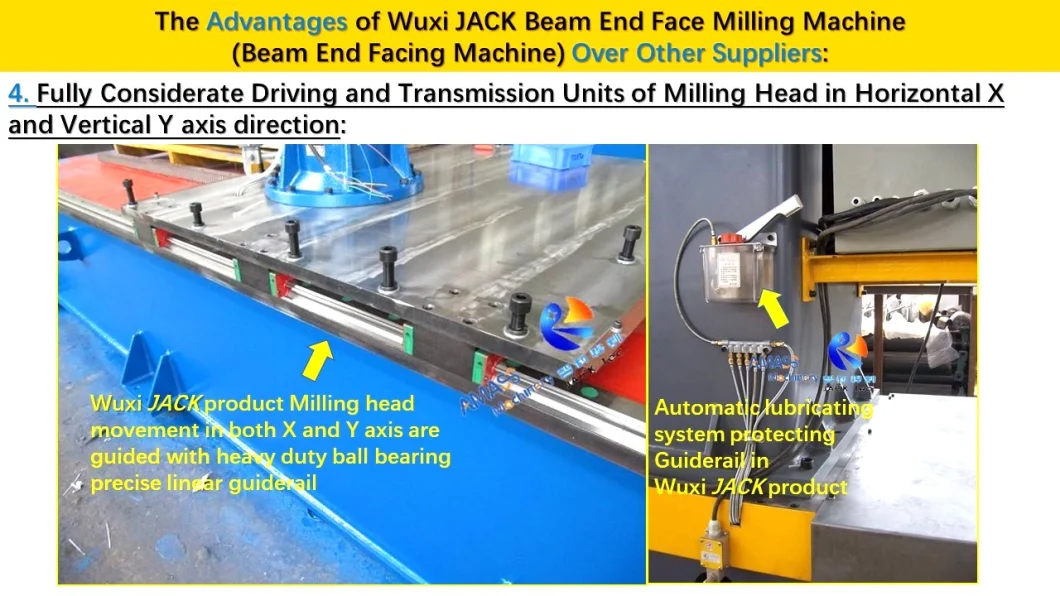

| Milling Head Guidance | Heavy duty precise linear guiderail |

| Operating Style | Operating panel and or CNC panel |

| Transport Package | Disassembled Into Wooden Case |

| Specification | End Face Milling height from 800mm to 6000mm |

| Trademark | Wuxi JACK and AMASS |

| Origin | Wuxi, China |

Packaging & Delivery

Package size per unit product 1500.00cm * 600.00cm * 1000.00cm Gross weight per unit product 15000.000kgProduct Description

A. Usage:1. DX series Steel Structure Beam End Face Milling machine is for polishing on end face of steel structure members: H /I/ BOX/ Cross Beam, etc.;The Common Seen Workpieces: (Fig.1)2. CNC-DX series can have end face milling with high efficiency and superior quality on all kinds of cross section shape workpieces, such as pipe, and any special structure members;(Fig.2)

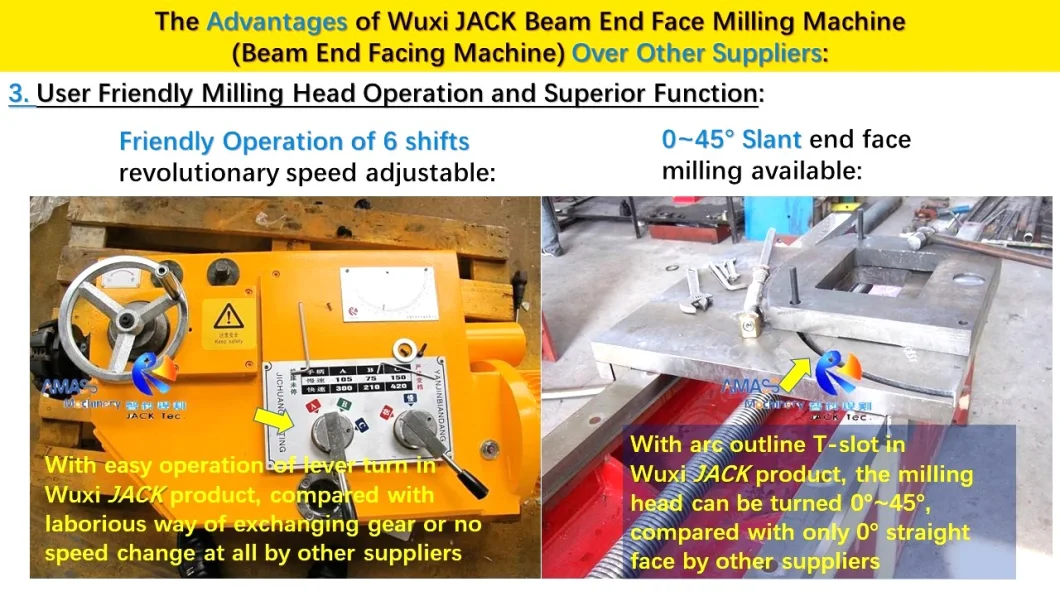

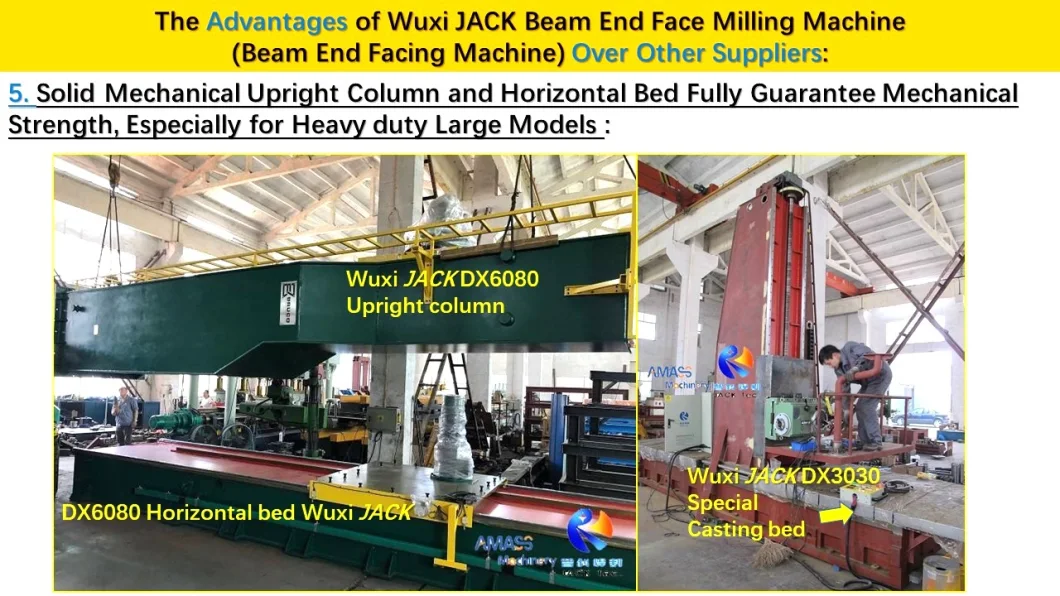

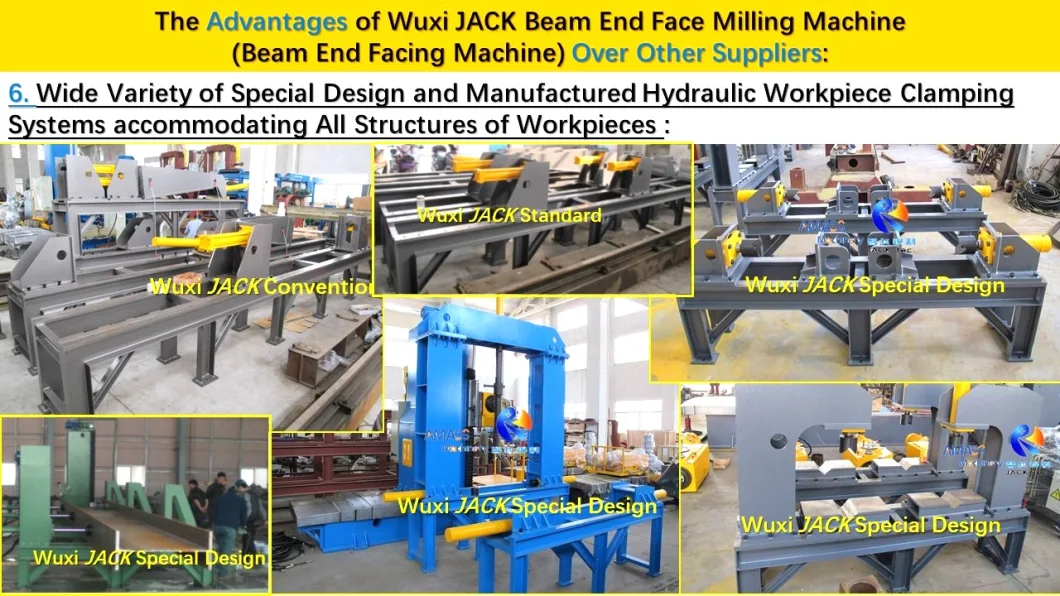

B. Advantages of Wuxi JACK (Wuxi AMASS) DX series Steel Structure Beam End Face Milling Machine:This Machine is superior product of Wuxi JACK (Wuxi AMASS). Below slides give graphical explanation on our superiorities:

C. Category and Models:1. Workpiece Size: From DX0810: 800mm height and 1000mm width; To DX6080: 6000mm height and 8000mm width;2. Control Way: There are 2 general types of the Beam End Face Milling Machine: Inverter control, and CNC control;1) Inverter control: DX0810 to DX6080, applicable for workpieces with regular 90° right angle cross section: H Beam, BOX Beam, T Beam, Cross Beam;2) CNC control: CNC-DX1010 to CNC-DX4080, applicable for any cross section workpieces:3) Wuxi JACK (Wuxi AMASS) Inverter and CNC Control Beam Pipe End Face Milling Machine: (Fig.3)

D. Structure and Main Units:One set of Wuxi JACK (Wuxi AMASS) DX Beam Pipe End Face Milling Machine is mainly composed of:1. Horizontal base bed2. Upright Column: 3. Milling Head Carriage: Wuxi JACK (Wuxi AMASS) milling head has 0°~45° swing angle, this is our exclusive capability. With this function, both straight and oblique face structure members can be end face milled;4. Facer Blade:5. Mechanical Feeding System:(Fig.4)

6. Control System: 7. Milling Head Movement Guide Rail in X and Y Axis: Heavy duty guiderail in Wuxi JACK (Wuxi AMASS) Beam End Face Milling Machine: (Fig.5)

In this way, high precision and stability end facing can be fully guaranteed;8. Guard Unit and Lubrication for Protecting Guiderail: (Fig.6)

E. Technical Parameters:

| Parameter | DX Series Inverter / CNC ControlBeam End Face Milling Machine | |

| Models | DX0810 ~ DX6080CNC DX1010 ~ CNC DX4080 | |

| Workpiece Cross Section Size Height | 800 mm ~ 6000 mm | |

| Applicable Workpieces | H Beam/ I Beam/ T Beam/ BOX Beam/ Cross Beam/ Pipe/ Any kinds of Special Design Structure Members | |

| Workpiece Length | 5m ~ 24 m, or any length available | |

| Horizontal End Face Milling Speed | 150~ 600 mm/min | Working speed, VFD, PLC control/ CNC control |

| Column and Milling Head Idle Speed | 1500 mm/min;2000 mm/min | Fixed speed |

| Vertical End Face Milling Speed | 150~ 600 mm/min. | Working speed, VFD, PLC control/ CNC control |

| Horizontal and Vertical End Face Milling Movement Guide | Heavy duty Precise Linear guiderail, assembled onto Machine base bed and upright column | |

| Milling Head Power | 7.5 kW | Made by Professional Supplier |

| Milling Head Spindle Revolution | 65 ~ 715 rpm | 6 grade Revolution adjustable |

Our AdvantagesAfter Sales ServiceFAQ1.

Q: What is the relationship between Wuxi AMASS and Wuxi JACK?

A: Wuxi AMASS and Wuxi JACK are the same company: Wuxi AMASS is wholly owned subsidiary of Wuxi JACK, for overseas trading Wuxi JACK products;

2.

Q: What is the nature of your company?

A: Business scope of Wuxi JACK and AMASS covers design, production and selling;

3.

Q: What is the range of your company product?

A: Wuxi JACK and AMASS is a professional supplier in Welding and Cutting Industry;Main products of our company include:1) Steel structure production equipment (H Beam/ BOX Beam/ T Beam);2) Edge Milling Machine;3) Structure member Beam end face milling machine;4) CNC Plate Cutting Machine;5) CNC Pipe Cutting Machine;6) Various kinds of conventional and special design welding equipment and machine;7) Various kinds of conventional and special design Straightening machine, etc.;

4.

Q: What is the strength of your company?

A:1) Wuxi JACK was founded by 3 senior engineers 15 years ago;2) Engineering team of our company has over 20 years experience on Welding and Cutting industry;3) Operation manager has 14 years experience working in an American Fortune Global 500 Dow Jones Industrial Index Company as senior Project Manager;4) The competitive edge of our company is special design products based on customer demand.

5.

Q: What are service terms of your company?

A:1) During business negation: a) Make technical proposal and quotation;b) Answering customer questions;c) Make final contract and technical agreement;2) During order to delivery value chain:a) Design, validate, and manufacture products for customers;b) Inform progress of manufacture to customers;c) Arrangement for package and shipment of products to customers;3) After sale service: a) Technical support on installation and commissioning at customer site;b) 1 year guarantee from the date of acceptance;c) Feedback any technical issues within 4 hours upon getting the notice;

6.

Q: Where is location of your company?

A: Wuxi city, Jiangsu province, 130km from Shanghai

Prev: Automatic Arc TIG MIG Longitudinal Seam Welding Machine

Next: 315-630 Semi-Automatic HDPE Pipe Butt Fusion Welding Machine/Fusion Butt Welder Workshop Machine

Our Contact

Send now