Automatic Orbital TIG Welder Machine for Tube to Tube Welding

Description

Basic Info

| Model NO. | TC series |

| Cooling Way | Air Cooling |

| Control | Automatic |

| Style | Handheld |

| Frequency Range | High Frequency |

| Electric Current | AC |

| Keywords | Small Pipe Orbital Welding Machine |

| Welded Pipe Diameter | 6.35mm~114.3mm |

| The Thickness of The Tube | 0.5-3mm |

| Warranty | 12 Months |

| Type | CNC |

| Transport Package | Export Package |

| Trademark | WINCOO |

| Origin | China |

| Production Capacity | 3000 Sets/Month |

Product Description

I. Closed Tube and Tube Welding Torch

I.PRODUCT DESCRIPTION

This welding gun is a special welding gun designed and developed for all position automatic welding of various pipe fittings.

I.PRODUCT PARAMETER

| Model | XD40 | XD80 | XD120 |

| Main distribution power | XD-20W Full position programmable power supply | ||

| Main weldable materials | Carbon steel, stainless steel, titanium alloy, etc | ||

| Welding pipe diameter range (mm) | 6.35-38.1 | 19.05-76.2 | 38.1-114.3 |

| The biggest wall thickness (mm) | 2.5 | 3 | |

| Welding gun cooling | Water cooling | ||

| Speed of rotation of welding gun (rpm) | 0.3~6.0 | 0.2~5.3 | 0.1~3.8 |

| Welding protection gas | Argon | ||

| Weight(kg) | 3.5 | 5 | 6.5 |

| Dimension(mm) | 377x129x42 | 438x155x44 | 540x195x54 |

Technological conditions

| Welded pipe diameter | Φ6.35mm-Φ114.3mm |

| The thickness of the tube | 0.5-3mm |

| Tungsten electrode diameter | Φ1.6mm-Φ2.4mm |

| The rotation speed of the welding clamp | 0.15rpm-4.5rpm |

| Pipe material | Carbon steel, stainless steel, titanium alloy, etc |

| Welding mode | Rotating non-winding all-position welding mode, with automatic reset function |

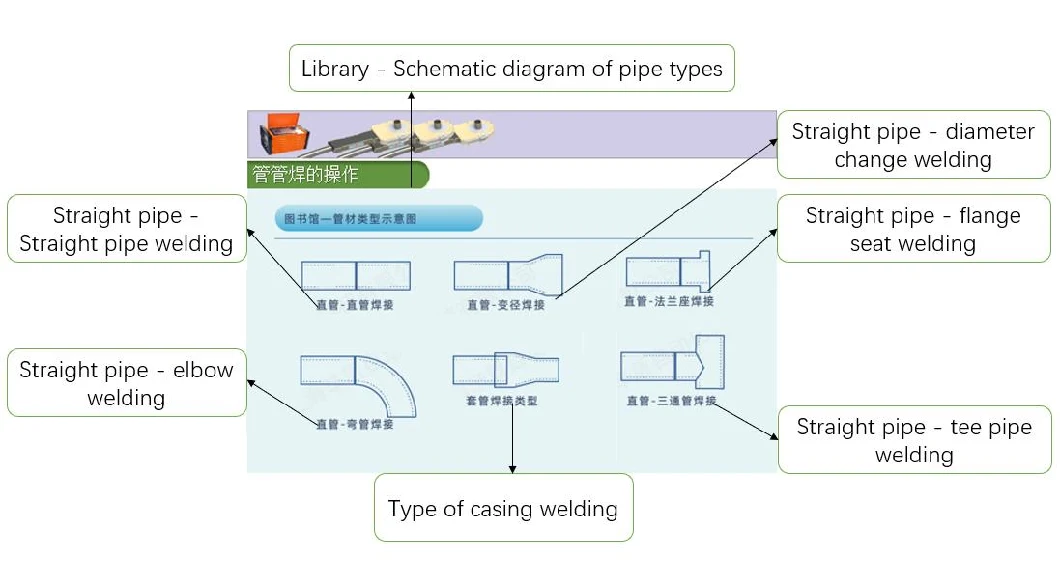

| Welded pipe fitting form | Straight pipe, tee, elbow, chuck, reducer and other butt joints, no beveling, self-fusion welding |

| Protection gas | Argon |

| Cooling water flow | 1000ml/min |

| When welding carbon steel tube, 5-8mm at the solder joint should be polished and rust removed to expose the primary color of metal | |

| The tube incision should be flat, vertical and burr free, and there is no gap between the two tubes | |

| Clean oil stains with acetone or alcohol | |

| The handle of welding clamp is equipped with operation button, which is convenient for personnel to operate and improve working efficiency | |

| When welding the pipe mouth, the length of the straight line segment that can be clamped should not be less than 20mm | |

| Draw a circle with the center of the welded pipe fitting as the center, R=80mm, and no obstacles within the range | |

I.PRODUCT ADVANTAGE

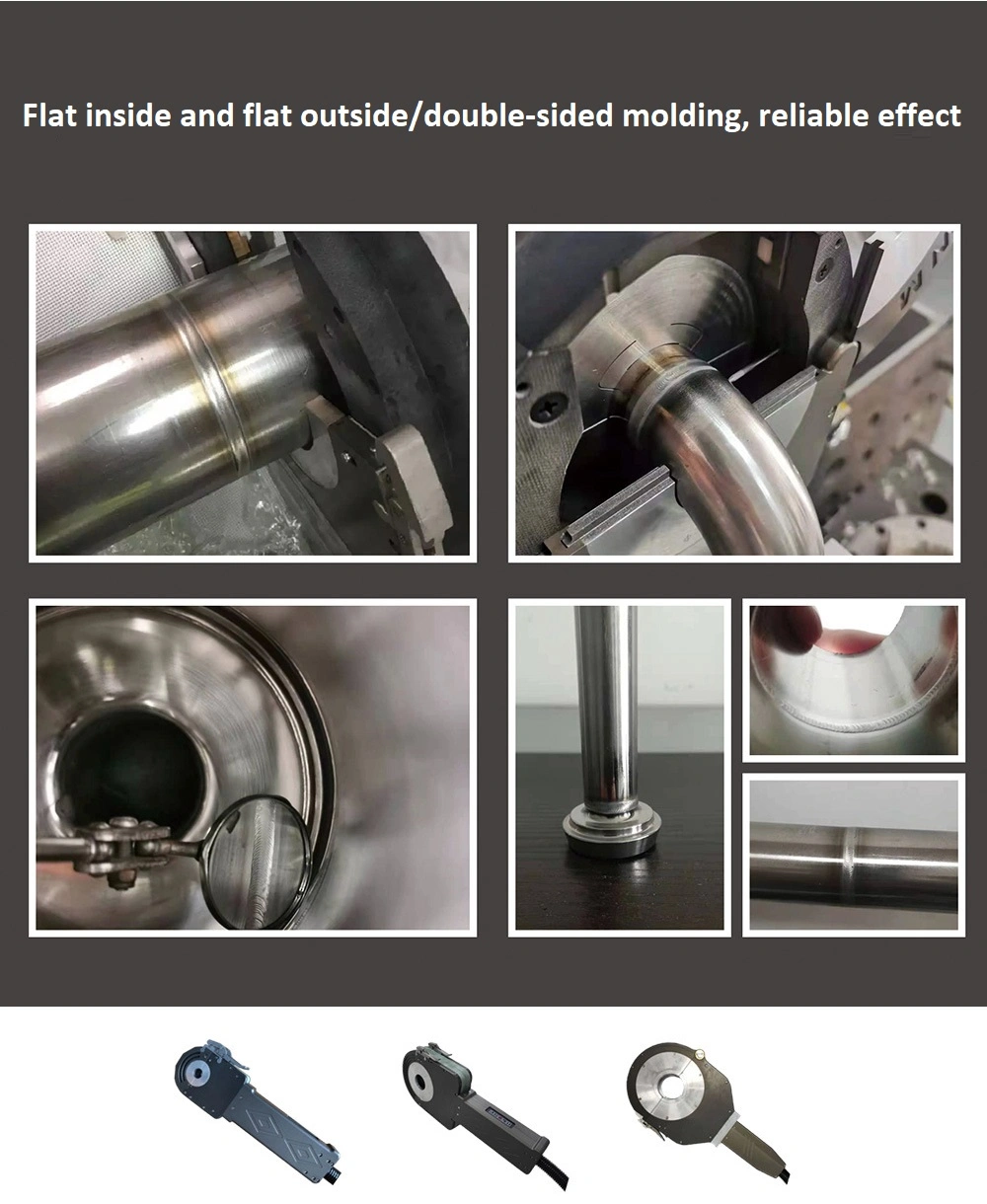

1, The motor is German planet motor2, The inner wall of the welding gun is water-cooled to improve the temporary load rate of the welding gun, so that the welding gun can work for a long time without heating3, The welding gun is made of core imported materials and aluminum for its light weight and reliability4, Patented clamp with flexibility to reduce pipe fitting requirements5, Special leakage hole shape, effectively ensure the weld beautiful6, With self-locking spring mechanism, it is convenient and firm to replace clamp7, Welding gun handle operation keys: forward turn, reverse, emergency stop, attenuation, start, indicator light

II. Overview of Control Power Supply

II.PRODUCT DESCRIPTION

Xd-20w digital program-controlled welding power supply is composed of control system, power supply system and cooling water tank. It has the characteristics of digitalization, easy operation and reliability. The control system adopts an open and upgradable operating system to centrally set, store and synchronize the function parameters of all-position welding. This power supply is specially designed and manufactured for thin-wall pipe/pipe welding. Mainly used in semiconductor, chemical, food, medicine, electronic pipeline and other industries, the overall design tends to be convenient, energy-saving, intelligent, human-machine interaction. One third less volume and weight than the original split. The integrated design is oriented to the construction of small space on site.

II.PRODUCT PARAMETER

| Model | XD-20W |

| The temporary load rate | 200A 60% /155A 100% |

| Welding current | 5-200A |

| No load voltage | 65V |

| Input voltage | AC220V±10% 50Hz/60Hz |

| Power | 4.5 KVA |

| Torch cooling | Built-in circulating water cooling |

| Display | 10 inch touch screen |

| Storable program | 99 pcs |

| Divisible intervals | 12 pcs |

| Insulation grade/Protection grade | F/IP21 |

| Control function | Dc/pulse current control, gas control, rotary motion, automatic/manual print control, water cooling control |

| Protect function | Over voltage, overload, leakage, arc starting failure and tungsten needle short circuit protection, missing item detection |

| Water tank capacity | 4L |

| Weight | 33KG( Contains 4L cooling water ) |

| Dimension | 510mm×353mm×340mm |

II.PRODUCT ADVANTAGE

1, 10 inch color screen, reasonable graphic design, the machine conforms to ergonomic operation habits2, Siemens PLC control system ensures fast operation, accuracy and reliability of welding process parameters. Low maintenance cost.3, Double cooling system, greatly improve the temporary load rate of welding gun4, Years of welding data accumulation, the summary of big data can be directly called5, Real-time welding monitoring, graphic design directly in the operation interface, simple and direct6, Light weight, easy to work at height7, Welding gun design is our exclusive patented technology, welding quality is guaranteed8, With one button printing and automatic printing function, built-in mini free maintenance printer9, The core components are imported from Germany, which can guarantee the stability of the equipment to a large extent

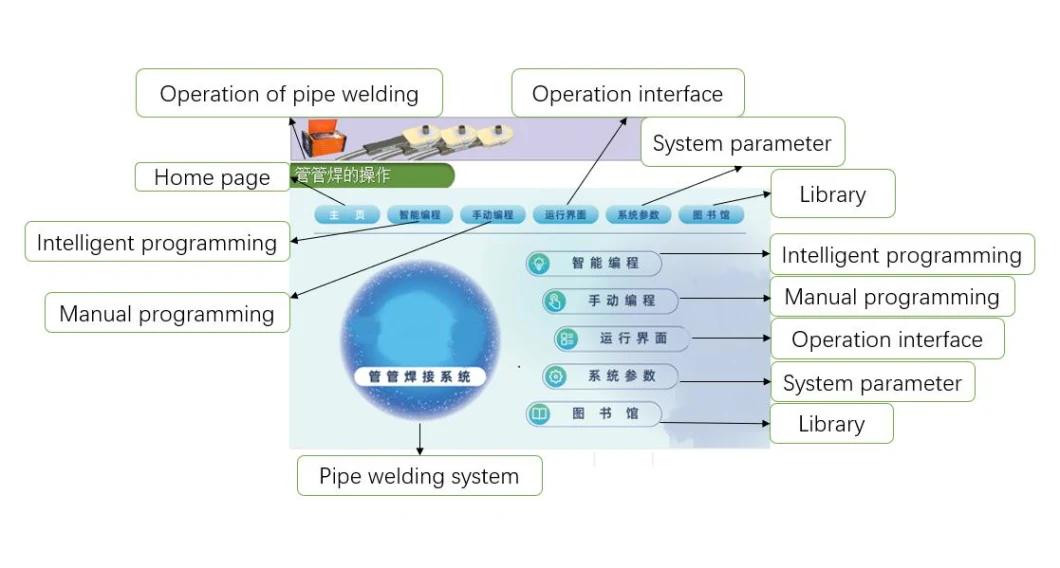

II.PRODUCT OPERATION DIAGRAM

Detailed Photos

Wincoo Engineering (WINCOO) is engaged in bringing the most suitable solutions/equipments for client, fabricators, EPC/C companies on pipe fabrication, tank construction, pipeline construction,industrial production lines, clean energy project and other industrial field.

Our Services & Strength*We have ability of providing workable solutions to support clients to be awarded with shorter project execution time, fewer man-hour cost and higher efficiency construction/fabrication method and better quality during phase of project bidding.*Based client's facility/site space availability, we are able to study/design and present matched configurations on project schedule, quality, cost and productivity to guarantee production pace is accordance with project requirement.*To support project execution, we are always ready to work as fireman to give prompt supply on project materials from different consumables, tools, equipments/machines to special merchandise. With flexibility, we are also glad to perform as procurement agent in China to seek required supply resources.FAQ

Q:Are you a factory or trading company?

A, Yes we are the trading company,but we have a lot of factories that have cooperative relationships, and we can get the best plan and price for you.

Q:Does the machine have CE certificate?

A:Yes, others certifications also can be sent

Q:What's the shipping method?

A: International express and sea transportation,Depend on customer.

Q:Can I use my own forwarder to transport the products for me?

A:Yes, if you have your own forwarder in China, you can let your forwarder ship the products for you.

Q:What's the Payment method?

A:T/T,L/C and other payment method, Depend on customer.

Q: What is our payment term?

A:We can accept the payment by T/T and Trade assueance .

Q: Can you send me the video to show how the machine works?

A: Certainly, we have made video of every machine.

Q: How can I know your machine works well?

A: Before delivery, we shall test the machine working condition for you.And we warmly welcome you to China for inspection.

Q:How to Place an order?

A:Please kinldy send us your order by email,we will confirm the PI with you .we wish to know the below:your details address,phone/fax number,destination,transportation way ;Product informaiton:item number,size,quantity,logo,etc.

Prev: High Efficiency Automatic Welding Machine/Tank Construction Machinery

Next: Automatic Assembly Welding Straightening Steel Structure H Beam Integral Machine

Our Contact