Automatic Assembly Welding Straightening Steel Structure H Beam Integral Machine

Description

Basic Info

| Model NO. | PHJ |

| Certification | ISO, CE |

| Automation | Automation |

| Flexible Production | Intelligent Manufacturing |

| Rhythm | Flow Production Line |

| Production Scope | Product Line |

| Function | Beam Making |

| Web Plate Height | 200-1500mm |

| Web Plate Thickness | 6-14mm |

| Flange Plate Width | 200-800mm |

| Flange Plate Thickness | 6-20mm |

| Transport Package | Wooden Case |

| Specification | 4100mm*2100mm*1600mm |

| Trademark | Zhouxiang |

| Origin | China |

| HS Code | 8468800000 |

| Production Capacity | 15sets/Month |

Product Description

| Web height | 200~1500mm |

| Web thickness | 6~16mm |

| Flange width | 200~800mm |

| Flange thickness | 6~20mm |

| Work-piece length | 6000~15000mm or as user's request |

| Assembly and welding speed | 0.35~3m/min |

| Main machine power | 17.5kW |

| Roller conveyor motor power | 0.75*4=6kW |

| Flux recycling machine motor power | 3*2=6kW |

| Pump station power | 4kW |

| Welding source power | 69kW*2=138kW |

Above are our standard model, it can be designed and manufactured according to customer's request. | |

This is a special machine for H beam direct assembling, welding and straightening, it combines assembly machine, automatic welding machine and straightening machine into one machine,thus improves productivity, reduces cost, and saves the installation space. It can produce H-beam and T-beam with high efficiency.

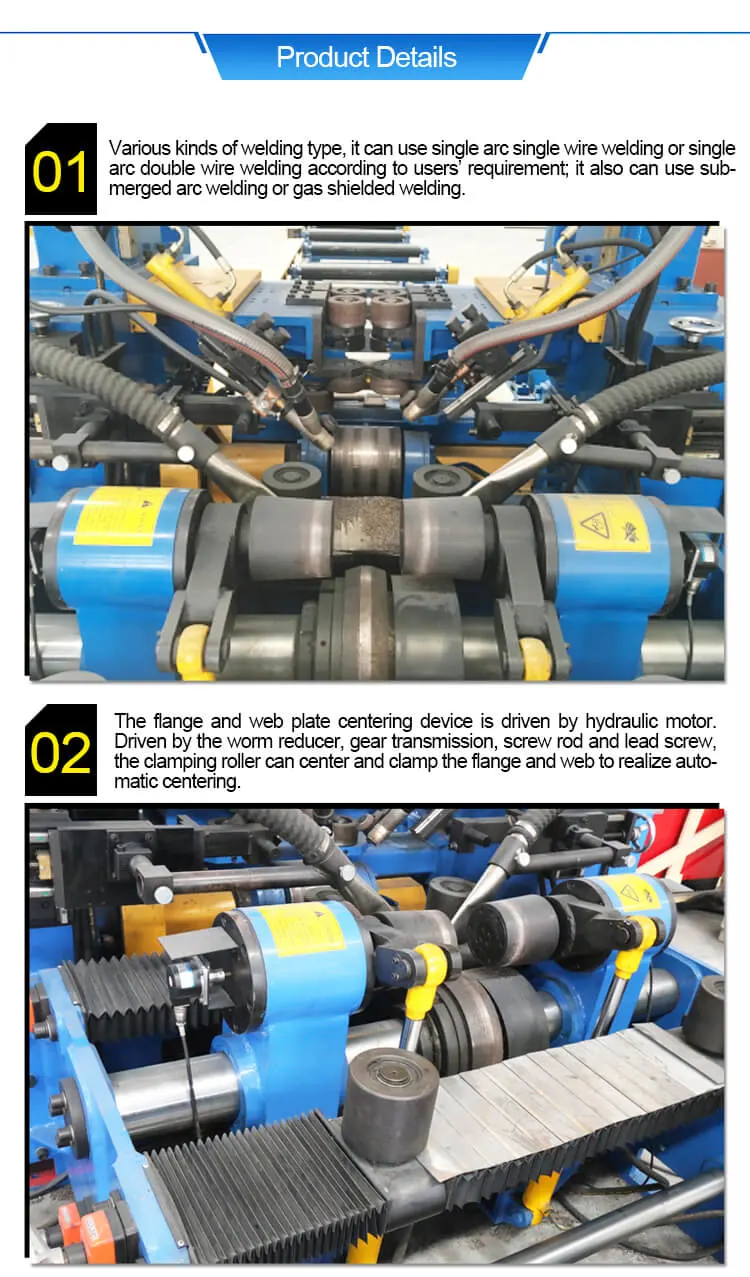

1.The flange and web plate centering device is driven by hydraulic motor. Driven by the worm reducer, gear transmission, screw rod and lead screw, the clamping roller can center and clamp the flange and web to realize automatic centering.

2.Firm welding torch fix mechanism is set up separately, it not only can adjust height and horizontal moving position, also can adjust the angle of welding torch on two direction, it guarantees the nice seam form.

3.Main transmission part adopt motor reducer for driving, the assembly and welding speed adjust adopts AC variable frequency speedadjusting, the speed adjustable range is 0.35-3 m/min.

4.Assistant straightening machine has special designed structure , the two straightening rollers can straighten workpiece automatically under the pushing of oil cylinder, straightening mechanism will not block the line of sight on seam, it is convenient to see the adjustment of welding torch and seam quality.

5.Assembling machine and assistant straightening machine can be designed and work separately.

6.This machine adopts centralized lubrication system, it can ensure that the wide distributed lubrication points can be lubricated well, and realize the purpose of good lubrication, reducing abrasion and prolong service life of the equipment.

Wuxi Zhouxiang Complete Set of Welding Equipment,founded in 1991,located in Wuxi city, about 100km from Shanghai.We have fixed assets of 150 million yuan,cover an area of 160,000 m2, staff 500 people,including more than 100 engineering and technical personnel.Our company was certified to ISO9001 Quality System Certification firstly in the industry and many products were certified to China Compulsory Certification(CCC).Our products sell well at home and abroad,including Europe,America,Southeast Asia,Middle East and other countries.Zhouxiang products mainly include CNC flame/plasma cutting machine,H beam light duty production line,H beam heavy duty production line,Horizontal H beam production line,H beam assembly welding straightening integral machine,Corrugated web H beam production line,Box beam production line, Welding manipulator, Rotator, Positioner,Edge milling machine,End face milling machine,Shot blasting machine series,kinds of plate rolling machine,Profile bending machine and welders,fiber laser cutting machine,CO2 laser cutting machine,laser tube cutting machine,Fiber laser cutting robot and Fiber laser welding robot etc.We have high sincerity to do business with customers all over the world and establish good friendships.

Prev: Automatic Orbital TIG Welder Machine for Tube to Tube Welding

Next: Automatic Arc TIG MIG Longitudinal Seam Welding Machine

Our Contact